Please Call (702) 324-6463 or email sales@nitevis.com

|

|

|

Categories |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Helpful Info Export Regulations

|

MR-10 1.8-10X

The MR-10 series stands out when a scope has to be versatile and highly effective at both extremes of its magnification range. A 37mm objective lens sits in front of a Turret Parallax Adjustment Locator (TPAL) system guaranteeing the sharpest image resolution possible throughout the 1.8-10X power magnification range. Target acquisition for accurate shots are effortlessly made from near pointblank to 1,000+ yards with the MR-10. When weather and light conditions are less than optimal the 12-position illuminated reticle system provides yet another advantage for taking your best possible shot. All MR-10 optics feature an Erector Repositioning Elevation Knob (EREK) system that maximizes gross elevation travel adjustment for maximum elevation adjustment where traditional turrets leave off. MIL and MOA reticle options are available in the MR-10 product line.

Reliable adjustments and extreme durability make this scope a very effective tool in the field. MOA or MIL reticles allow you to use whichever unit of measure you desire. Optional finish colors available at an additional charge. Scope body, eye piece, objective housing and any and all other body parts are made with 6061-T6 aircraft aluminum and are then coated with a matte black type III hard anodizing. Duel elevation and windage rebound springs will insure decades of reliable and accurate adjustments

| SPECIFICATIONS | |

| Name | MR - 10 |

| Length | 13in |

| Weight | 1.50 lbs. |

| Magnification | 1.8X - 10X |

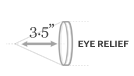

| Eye Relief | mm/3.5 inches |

| Base Color | Matte Black Type III Hard Anodizing |

| Base Objective | 37mm |

| Base Knob Windage | US#1 1/4 MOA Slimline |

| Base Parallax | FIXED - Standard |

| Base Knob Elevation | US#1 1/4 MOA Slimline |

| Base Tube | 30mm Standard |

| Base Reticle | MOA Scale TYPE 1 - Mil-Dot |

| Base Eyepiece Housing | Low Profile - Rapid Focus |

| Base Eyepiece | Rapid Focus |

| Field-Of-View (ft @ 100 yards) | 41.6 - 12.8 |

| Objective Lens (in) | 37mm |

| Elevation Range (MOA) | 70+ |

| Elevation Range (MILS) | 22.5 |

| Windage Range (MOA) | 39L/39R |

| Windage Range (MILS) | 11L/11R |

| Other | |

| Upgrade | No |

| Area of Travel (MOA) | 30mm = 85 |

Matte Black type III is the hardest scope coating in the industry it is scratch proof and chemical proof. This coating can with stand severe abuse, salt fog tests have been conducted internally and externally by outside military testing. Sulfuric acid is the most widely used solution to produce anodized coating, while coatings thicker than 25 μm (0.001") are known as Type III, hardcoat, hard anodizing, or engineered anodizing. Standards for thick sulfuric anodizing are given by MIL-A-8625 Type III, AMS 2469, BS 5599, BS EN 2536 and the obsolete AMS 2468 and DEF STAN 03-26/1.The Matte Black finish is matte black dye.

Matte Black Type III Hard Anodizing |

Cerakote Titanium* |

Cerakote Coyote Tan* |

Cerakote Tungsten* |

Cerakote Forest Green* |

Cerakote Nut Brown* |

Cerakote MIL-Spec Green* |

Cerakote Flat Dark Earth* |

Cerakote FS Brown Sand*

|

* Note: This extends the build time by 2 months Cerakote coatings are formulated for specific applications and technical requirements. Current Cerakote product lines include coatings specifically for firearms, exhaust systems, pistons and high wear applications. In addition, Cerakote is available in a line of ceramic clear coats. If you want to match the color of your scope to your rifle or any other gear, Cerakote is the product for you. |

(Buy This Separately)

Accessories:

Unlike other scope companies, U.S. Optics allows the customer to customize their scope down to even the color. Whether it is a different color Type III Hard Anodize, or a Cerakote color, we can match the look of your rifle/gear on the scope. Because we are building all the scopes in house, we don\'t need to mask off the crucial parts, we coat each part before the scope is assembled for a high quality job.

Matte Black type III is the hardest scope coating in the industry it is scratch proof and chemical proof. This coating can with stand severe abuse, salt fog tests have been conducted internally and externally by outside military testing. Sulfuric acid is the most widely used solution to produce anodized coating, while coatings thicker than 25 μm (0.001") are known as Type III, hardcoat, hard anodizing, or engineered anodizing. Standards for thick sulfuric anodizing are given by MIL-A-8625 Type III, AMS 2469, BS 5599, BS EN 2536 and the obsolete AMS 2468 and DEF STAN 03-26/1.The Matte Black finish is matte black dye.

Cerakote coatings are formulated for specific applications and technical requirements. Current Cerakote product lines include coatings specifically for firearms, exhaust systems, pistons and high wear applications. In addition, Cerakote is available in a line of ceramic clear coats. If you want to match the color of your scope to your rifle or any other gear, Cerakote is the product for you.

One of the most important parts of a rifle scope is the objective. The objective determines many qualities of the complete optical system. Magnification, exit pupil and light gathering are some of the most critical points. The larger the objective diameter, the more light will be gathered into the optical system. The smaller the objective, the smaller the exit pupil, and the longer the objective, the more magnification is gained.

Your reticle decision is one that will aid in many points of your scope. If you are choosing MIL, MOA or IPHY we have a reticle for you. Various reticle models have different ranging stadia, line thicknesses and design to aid the operator in hold off\'s, ranging and fine precision shot placement. If you don\'t see a reticle that suits your needs, contact us and we can design and build one exactly the way you want it.

Elevation knobs are one part of a scope that gets used a lot and having a repeatable, durable knob will provide many years of use. Whether you are using the EREK, #1 or #3, all knobs are made of stainless on stainless, or stainless on brass. Each knob is hand lapped to insure exact repeatability and accuracy. All knobs use an encapsulated tungsten ball with a stainless threaded housing so our technicians can adjust the tension for the perfect feel.

Your weapon doesn\'t have to be lonely and incapacitated during the extremes. Accessorize it with our custom covers, bags and other great items.

![]()

Home | Contact Us | About KERIF | Export Regulations | How to Order

![]()

(702) 324-6463 / (702) 869-8451 FAX